Specialist advice

+7 (343) 204-93-93

or fill in the feedback form:

- Designed for seam heights greater than 1650 mm (65 in.)

- For coal, trona and potash applications

- Throughput up to 1,814 tonnes (2,000 tons) per hour

- 3.5” pitch chain size

- Pick force up to 130,000 lbs.

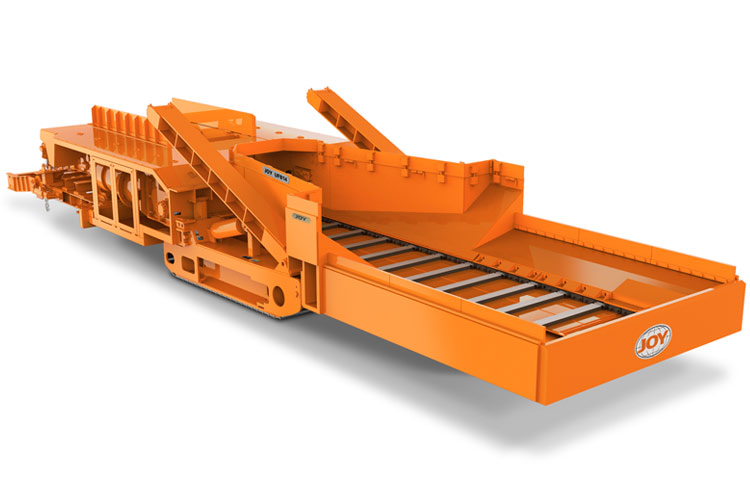

Joy feeder-breakers provide a highly reliable, productive means for continuous feeding and breaking of most bedded, mined material – including wet, dry, sticky or a combination thereof – in a broad range of configurations for both surface and underground applications. The feeder-breaker is the connection between the mining system and material handling system, allowing both systems to operate at maximum efficiency and productivity. The UFB-14 feeder-breaker, designed for seam heights greater than 1,650 mm (65 in.), cuts your operating costs and increases your mine production by allowing your mining, haulage, and conveying systems to work at their most efficient rates. The UFB-14 provides a highly mobile crushing solution to maximize your haulage productivity. Since the UFB-14 is located closer to the working face, haulage distances and travel times are kept to a minimum.

Designed for increased mine efficiency

- Surge capacity allows haulage equipment to discharge mined material at its maximum rate

- Material throughput is fully variable up to 1,814 tonnes (2,000 tons) per hour

- Optidrive variable frequency drive (VFD) system offers variable speed control equivalent to 25 to 100% of the rated throughput

- Water-cooled and air-cooled drives available

- Powerful rotary pick breaker, capable of fracturing material using up to 200 MPa (30,000 PSI) unconfined compressive strength, reduces mined material to a consistent, easily handled size

- Steady discharge rate virtually eliminates spillage, while reducing belt wear

Designed for durability

- All-welded frame construction means low maintenance and long working life

- Hard-surfaced chromium carbide deck overlay ensures long deck life

- Alloy steel flights and shafting allow smaller sized components while still providing superb tensile strength

- Breaker picks and pick force, designed for your requirements, handle tough material mixtures

- High-strength conveyor chain, with hardened pins and bushings, delivers long life, low maintenance, and superior dependability

Designed for maximum mobility and performance

- Available with optional Integrated Continuous Tramming (ICT) crawlers that include:

- 20” crawler pads for lower ground pressure and improved traction in varying bottom conditions

- A planetary crawler drive with reversible cap for free-wheeling capability

- Designed to maximize tractive effort for ease and speed of relocation

- Maximum pad widths to ensure excellent flotation in all tram conditions

- The breaker drives are electro-mechanical, direct-drive utilizing robust geared drives for maximum performance, reliability and availability.

Designed for easy maintenance

- Strategically located standard controls provide the easiest possible maintenance and troubleshooting

- Bolt-on flights to allow easier installation and removal

- Enhanced tail shaft designs for longer life

- Longer life conveyor sprockets and chain

Designed for your mining application

- Intake ends, custom designed to meet your haulage needs, include ram car, swing gate, and three-way dump options

- Staked or hinged sideboards come in various heights for additional capacity

- Fully variable speed designs to match capacity to application

Designed for operator safety

- Fire suppression

- Centered control valves

- Panic strip

- Tram enable switches

- Pull cords

- Remote tram controls (radio and umbilical)

| Overall width (at intake end) | 2,844 to 3,759 mm | 112 to 148 in. |

| Conveyor width | 1,117, 1,270, 1,422 and 1,574 mm | 44, 50, 56 and 62 in. |

| Overall length | 10,058 to 11,684 mm | 396 to 460 in. |

| Weight | 36,287 to 45,350 kg | 80,000 to 100,000 lbs. |

| Seam height | 1,854 mm | 73 in. |

| Processed material | Run-of-mine coal with high percentage of rock content | |

| Throughput standard (variable) | Up to 1,360 TPH | Up to 1,500 TPH |

| Breaker diameter | 533 to 864 mm | 21 to 34 in. |

| Breaker pick force (variable) | Up to 60,000 kgs | Up to 130,000 lbs. |

| Material compressive strength | Up to 200 Mpa | Up to 30,000 PSI |

| Ground clearance: Intake end Discharge end | 50 to 432 mm 305 to 686 mm | 2 to 17 in. 12 to 27 in. |

| Frame height | 914 to 1295 mm | 36 to 51 in. |

| Total horsepower (variable) | 225 kW | Up to 300 hp |

| Intake end design | Ram car 3-way dump Hoppered with sideboards | |

| Mobility | High torque Free-wheeling extreme duty crawlers Optional tram speeds 30, 42, and 50 fpm (9.14, 12.8 and 15.2 mpm) available | |

| Available tractive effort | Up to 64,410 kg | Up to 142,000 lbs. |

| Drawbar pull | Up to 45,359 kg | Up to 100,000 lbs. |

| Flexibility of configuration | High | |

Optidrive VFD

Joy Optidrive, an AC variable-frequency drive system, integrates software with the electronic and mechanical systems to provide the following features:

- Conveyor speed control: Provides variable conveyor speed capability, allowing precise control of the equipment’s capacity

- Prevents breaker overloads: Feedback circuit monitors breaker motor amps and regulates conveyor speed to prevent overloads