Specialist advice

+7 (343) 204-93-93

or fill in the feedback form:

- Ratings up to 1,750 tonnes

- Widths of 1.5, 1.75, and 2.05 meters

- Heights from 0.8 to 7.8 meters

- Leg bore sizes ranging from 125 to 480 mm

- 15,000 to 90,000 cycles versions available

- Integrated RS20S electronic control system, providing full face automation

- Integrated Compak hydraulic control system for multifunctional controls

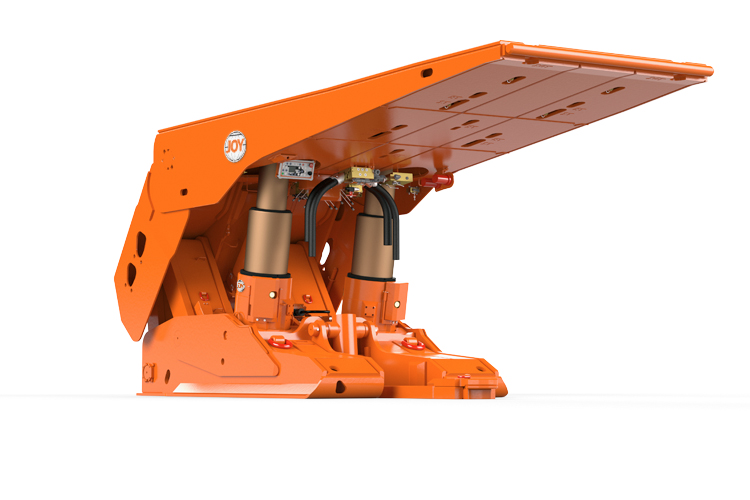

Joy powered roof supports, for high-capacity longwall applications, are custom designed to meet your exacting cycle and operating requirements:

- Ratings up to 1,750 tonnes

- Widths of 1.5, 1.75, and 2.05 meters

- Heights from 0.8 to 7.8 meters

- Leg bore sizes ranging from 125 to 480 mm

Industry leader

- Over 60 years of experience in designing and manufacturing powered roof supports

- ISO 9001 approval

- CE Certification

- UKAS Accreditation Testing Laboratory

- Electronic and hydraulic SIL-rated products

State-of-the-art design process

The Joy design process includes:

- Finite element analysis (FEA)

- Fatigue analysis

- Prototype static and dynamic load testing

This analysis and testing allows for optimized hydraulic efficiency to maximize flow and minimize pressure drops and turbulence, keeping support cycle times to a minimum.

In addition, the structures undergo overload tests of up to 20% and are fatigue tested at twice their rated load. The structural design of the powered roof supports is respected throughout the mining industry for attention to key fabrication details:

- High-strength steels

- Automated welding for increased weld integrity

- Elimination of stress-prone transverse welds

Robust leg construction

- 125 to 480 mm leg bore size range available

- Single, double, and triple telescopic designs available for maximum open-to-closed height ratios

- No welds on leg cylinder for high fatigue life

- Internal seals work with cylinders for extended service life between rebuilds

- Patented locking system for leg feeds

- Extruded design with improved leg geometry for closer positioning to the vertical in a given seam height, resulting better load application to the mine roof

- Large capacity feeds for large-bore diameter legs requiring high flow

- High cycle times to match shearer cutting rates

- Elimination of stress risers

Superb load-bearing capabilities

- Robust load input area at end of legs using four large steel castings

- Memory flexible inserts used around leg interfaces keep areas free from debris build up that can lead to bending loads

Compak valve system

- Multifunctional control with solenoid-actuated pilot circuits receiving instructions from either the operator bush button or RS20S Faceboss electronic control system

RS20s Faceboss control system

The RS20s Faceboss system requires no special gate-end computer for control and is the fastest and most powerful shield control system ever supplied by Joy. These systems are globally fitted on the most automated and productive longwalls.

The RS20s Faceboss system is supplied with a complete automation library of over 100 face cutting sequences to suit virtually all conditions. Using shearer initiation with gate-end automation, no operators need to be specifically deployed for shield operation.