Specialist advice

+7 (343) 204-93-93

or fill in the feedback form:

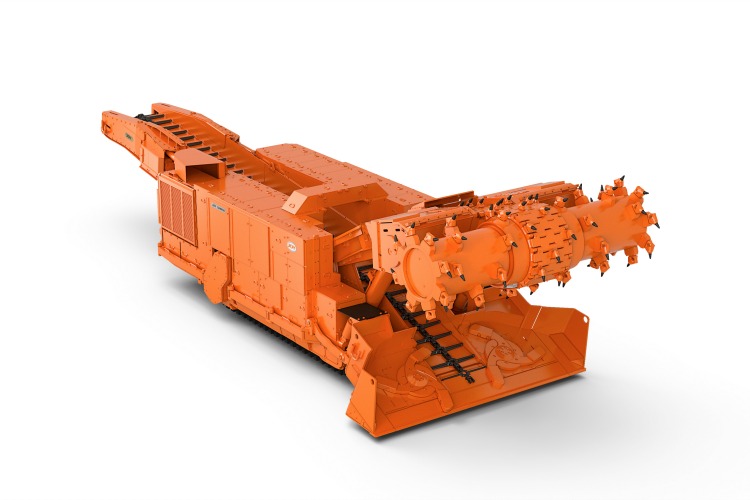

- Ripperveyor cutting head system

- 1473 mm (58 in.) cutter head diameter

- Cooling system designed to meet mine’s water requirements

- Bolted construction to meet shaft entry requirements

- Individual motors with direct-drive transmissions to power the cutter, traction, gathering, and hydraulic systems

- Outboard access for motors, gearcases, controllers and other major components to reduce downtime and maintenance costs

- Remote radio control operations, with different frequencies available for multi-machine sections

- Optidrive AC electronic system to provide smooth transmission responsiveness

- Faceboss control platform to facilitate an optimal balance of production rate and cost

- Dual scrubber systems for dust control (optional)

The 12HM36 continuous miner, with a dual gathering head system, is ideal for industrial mineral mining applications, including trona, gypsum, potash, and salt. The 12HM36, with a 1473 mm (58 in.) cutter head diameter, is one of the largest and most powerful drum-style continuous miner in our product lineup.

Cutting system

The 12HM36 is a Ripperveyor cutting head system, with a variety of cutter bit lacing configurations available.

Bolted construction

Since many industrial mineral mines have shaft restrictions, the 12HM36 comes in several bolted configurations to accommodate these restrictions. This continuous miner is designed to be assembled on site without, or with very limited, component welding.

Traction system

All 12HM series machines include heavy-duty crawler chain, along with a heavy-duty drive system, to effectively tram the machines.

The 12HM36 traction system includes our patented Optidrive AC electronic system, which is coupled to a compact, all-gear transmission to provide smooth, reliable service. The cutter motor feedback and the traction differential features optimize sump performance even in the most demanding applications. Finally, the brushless AC traction motors are highly reliable and require minimal maintenance.

Conveyor system

The conveying system on all 12HM series machines features a 965 mm (38 in.) conveyor to provide increased production capability. 12HM series machines come with a standard single rear conveyor drive; however, an optional dual rear conveyor chain drive is also available.

High-voltage operation

All 12HM series continuous miners are designed operate at 2300V 60Hz, 4160V 60Hz, or 3300V 50 Hz. High-voltage operation also provides lower costs associated with component failures and the potential to use a trailing cable with a smaller conductor size (as compared to a medium-voltage miner).

Haulage system compatibility

The 12HM series continuous miners can be customized, using different conveyor lengths and conveyor chain speeds, to optimize our batch or continuous haulage systems. In addition, we can also supply a conveyor to match an attached haulage system.

| Machine weight | 117,935 kg | 260,000 lbs. |

| Maximum cutting height | 4,615 mm | 182 in. |

| Minimum cutting height | 2,095 mm | 82 in. |

| Minimum tram height | 1.8 m | 71 in. |

| Conveyor width | 965 mm | 38 in. |

| Cutterhead power @ 2300V 60 Hz | 250 kW | 335 hp |

| Total machine power @ 2300V 60 Hz | 840 kW | 1126 hp |

Faceboss control system

Competitive and market pressures mean that you have to produce product at an ever-increasing rate, while always striving to decrease your cost per ton. These goals are only made more difficult by the worsening attributes of available reserves and deteriorating operating conditions.

The Faceboss control system enables your operators to operate equipment at an optimal balance of production rate and cost per ton using a powerful tool set that includes operator assistance tools, automated sequences, advanced diagnostics, machine performance monitoring, and analysis tools. Faceboss is the standard control system platform on all Joy underground mining equipment, which ensures that you receive the same level of optimization for all your Joy equipment.

Optidrive AC

Joy Optidrive, an AC variable-frequency drive system, integrates software with the electronic and mechanical systems to provide the following features:

- Increased tram speed: Significantly increases the tractive effort available, improving the equipment’s ability to climb gradients and negotiate difficult roadway conditions

- Regenerative braking: Supplements the mechanical brakes, allowing them to run cooler with extended wear life; regenerative braking is highly effective at automatically maintaining constant speeds when descending gradients

- Less maintenance: No commutator brushes to inspect and replace mean AC traction motors are typically more reliable, more durable, and require less maintenance than DC traction motors