Specialist advice

+7 (343) 204-93-93

or fill in the feedback form:

- High input/output efficiency ratio, for reduced and optimized energy consumption

- Easy maintenance with long intervals and service kits available

- Single body drifter prevents seizing and breakage issues

- High frequency rotation engines designed for high speed drilling

- New generation of hydraulic thrust increases penetration speed, shanks life, rods and bit

- Optional hydraulic reverse percussion for long hole drilling applications

- Easy adaptation on carrier

- Large hydraulic hoses setup and configurations

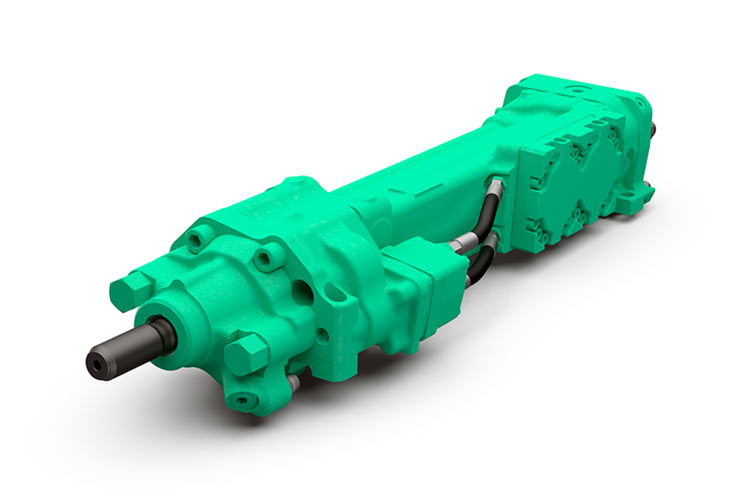

Montabert drifters are the result of years of experience in hydraulic rock breakers and drifters design and manufacturing. In-depth knowledge of shock wave transmission and percussion mechanism theory has allowed our engineers to be the first to develop new concepts such as hydraulic dampening and progressive blow energy.

Our close relationship between manufacturing and engineering, ultra modern machining tools, and sophisticated heat treatment workshop in our Saint-Priest plant, are some of the factors that have allowed us to offer hydraulic drifters which are recognized as the worldwide leaders for:

- High performance

- Best reliability

- Long maintenance intervals

- Low tool consumption

Design excellence

Energy recovery valve

This valve allows the piston rebound energy to be utilized for the next blow, giving a definite advantage to the HC series drifters:

- Better efficiency

- No internal peak of pressure source of cavitation

- Best drifter protection

Progressive blow energy

The unique design of the piston generates a perfect, long trapezoidal-shaped shock wave:

- Better energy transmission to the bits

- Minimum stress into the drill string

- Better bit penetration

Hydraulic dampening system

The action of the dampening piston not only absorbs the lost part of reflected energy but also ensures a constant thrust onto the tools:

- Optimum shock wave transmission

- Protection of the drifter and tools

- Reduced vibrations

Hydraulic reverse percussion

The optimal hydraulic reverse percussion system ensures a real back hammering:

- Tool extraction in fractured ground

- No rods left in the hole

Straight holes drilling

When associated with Montabert drilling controls