Specialist advice

+7 (343) 204-93-93

or fill in the feedback form:

- Ideal for both mining and industrial applications, including handling of wet or sticky materials

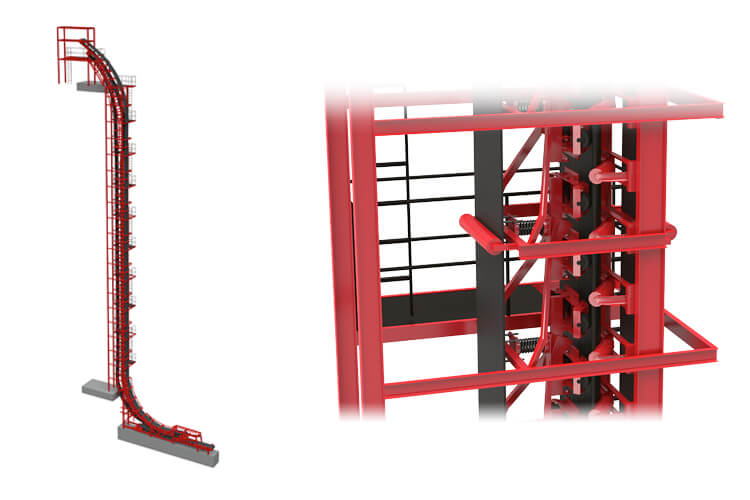

- Ideal option for steep angle applications

- Pressing components secure material toward center of belt, sealing the belt edges together

- Uses standard idlers and rolls for quick and easy component replacement

- May be shortened or lengthened or have the conveying angle altered for a new location

- Mobility options are available

Designed for multiple industries and materials

The HAC system is ideal for conveying a wide range of materials, including:

- Coal

- Tunnel muck

- Gravel

- Wood chips

- Copper ore

- Gypsum

- Slag

- Excavated silts

- Sands

- Clay

- Grains

- Refuse

- Municipal sludge

Designed for high performance

One of the secrets to high performance capabilities of the HAC system technology is in its use of pressing components. Fully-equalized pressing mechanisms secure material toward the center of the belt while gently, but effectively, sealing the belt edges together.

During operation, the conveyed material remains sealed between the carrying and cover belts, decreasing the potential for spillage along the conveyor length.

The pressing mechanism does not confront the material; instead, it conforms to the surface shapes using soft, gentle pressure. This results in the preservation of product quality.

Standard, smooth surface belts allow continuous cleaning by belt scrapers or plows. This is especially important in handling wet and sticky material.

Designed for flexibility

The HAC system is adaptable to multi-module sections using self-contained units, as well as single-run systems. In the both cases, the conveyor unit may be shortened or lengthened or the conveying angle may be altered according to the requirements of a new location. HAC systems can be mounted on rails, rubber-tired, or crawler-type transporters.

Designed for ease of maintenance

The HAC system uses standard conveyor idlers and rolls for quick and easy component replacement.